Refrigerator Optimizer Manual Usage and installation manual

This is the user/installation manual of the Refrigerator Optimizer.

- TL;DR

- Kit version

- Installation

- Commissioning

- General notes

- Usage

- Special features

- Troubleshooting

- Comments

TL;DR (Too Long; Did't Read)

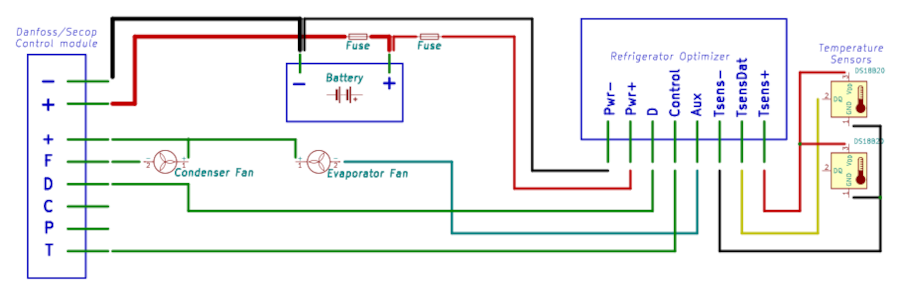

Ok, for those that are in a hurry and think they know it already, and just want the connection diagram...

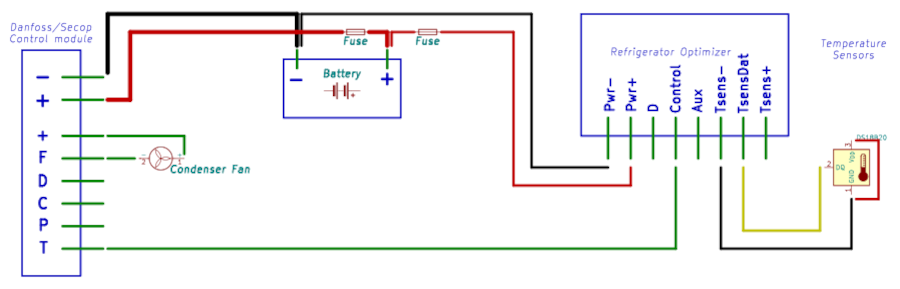

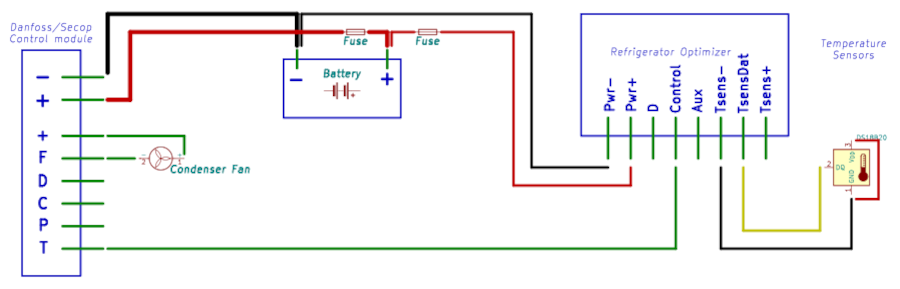

This is how you connect the things together in its most basic form. For the vast majority of all users, it doesn't get more complicated than this.

Sure you are a pro, but for the rest of us... Please read the rest of this installation manual, there are more options and useful installation hints.

Kit version

If you ordered a so called kit-version, where you do the end assembly yourself, you first have to assemble the kit. The kit is pre-programmed, you only have to put the pieces together. See for detailed instructions the Generic Assembly page. In addition, if you ordered a relay, you also need to install this prior to installing the LCD.

Installation

Physical installation of the Refrigerator Optimizer

The Refrigerator Optimizer is intended to be mounted outside of the refrigerator. The only part needed inside the refrigerator is the temperature sensor.

The Refrigerator Optimizer can be installed up to 3 meters away from the refrigerator.

The tidiest installation is achieved when the Refrigerator Optimizer is embedded into a panel. The white bezel can be used as a template for the holes for the bolts.

Another option is to install it in the optional matching casing so that it can be mounted as a self contained unit onto a wall.

The Refrigerator Optimizer does not require any airflow or cooling.

To embed the Refrigerator Optimizer inside a panel (or box), you just cut a hole large enough to get the circuit board through, and have the bezel and flanges of the front panel covering the cutout. The supplied 3mm stainless steel alan bolts are 10mm long.

The required cutout is 90mm x 50mm. You can make the cutout slightly bigger, the cutout will be covered by the bezel and flanges of the front panel. But make sure you leave enough space for the mounting screws.

Physical installation of the temperature sensor

Be careful when doing any work inside the refrigerator. If you damage any of the tubes that carry the refrigerant, it will result in a costly repair or a total loss of the refrigerator. Double check before drilling any hole or bending any tube that it can be done without damaging anything.

The Refrigerator Optimizer needs a sensor inside the refrigerator to measure the temperature.

These are your options:

- If your refrigerator has a mechanical thermostat inside the cabinet, this thermostat will no longer be used. You can follow its cable that runs to the compressor and use the exit hole to route the cable of the new sensor through, or reuse this cable for the new sensor. The digital sensors can be connected with only two wires if your cable run is less than 2 meters, and after gutting the mechanical thermostat out of its housing, you could mount the new sensor inside. If you do that, make sure to drill some holes in the thermostat housing to allow air to reach the new sensor.

If your refrigerator has an electronic thermostat outside the cabinet, with a temperature sensor already inside, you can possibly reuse this sensor, so you don't have to modify anything inside the fridge. If you want to go this route, it is best to test-run the Refrigerator Optimizer first to see if it can read the temperature from this sensor. Note that if you want to reuse the old sensor, you can not use an additional sensor. The Refrigerator Optimizer can only use dual sensors if both are digital sensors.

If you can't use the original cable routing or original sensor, before you drill a hole through the refrigerator, double check that the tube from the evaporator to the compressor is not routed anywhere in that area. Make sure to seal the hole afterwards so that moist air can not enter the refrigerator.

If you want to use an additional sensor on the evaporator, this is only possible if both sensors are digital sensors. The good news is that you can wire them in parallel, so even with two sensors you only have to route a single cable to exit the cabinet.

Give some thought about where you want to install the temperature sensor. Try to find a "neutral" spot for the probe. Too close to the evaporator and it will sense a drop in temperature as soon as the compressor starts running, before the content of the cabinet has cooled down. Too close to the door and it will immediately see a dramatic increase in temperature as soon as you open the door. Too much behind a lot of stuff in the refrigerator, and it will take a long time before any change in temperature will be registered.

If you also install the optional evaporator temperature sensor, obviously this sensor needs to make firm contact with the evaporator, on its coldest point. You might be tempted to drill a hole in the evaporator, but make sure that you keep a healthy distance away from the tubes that run inside. A safer option is to use some epoxy glue. It would be a good idea to use a little bit of insulation foam to cover the rest of the probe, so it really measures the temperature of the evaporator and not its surroundings.

Electrical

Power supply

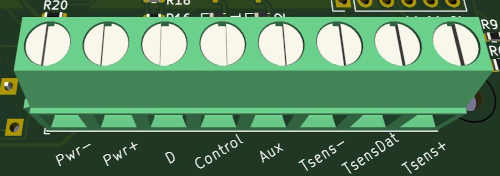

The Refrigerator Optimizer needs its own power supply, connected to the terminals labeled "Pwr-" (minus) and "Pwr+" (plus). It may be tempting to tap into the wires that feed the refrigerator, but don't do that! It is better to power the Refrigerator Optimizer from a separate wire set (plus and minus) straight from the bus bar or battery. There are two reasons for this:

- The Refrigerator Optimizer takes decisions based on the system voltage. If you tap into the power supply of the refrigerator, it will likely experience a voltage drop when the compressor runs. This voltage drop can easily be 0.5V, which will throw off the voltage as measured and indicated on the display by the same amount.

- The refrigerator itself needs a stable power supply. If you tap into its power supply, you are likely to introduce additional resistance, especially after some time when corrosion of the splice takes its toll. In the worst case, the refrigerator will cease to run.

Also, make sure that you use a proper fuse for the wire that you use. Fuses are for protecting the wire, not for protecting the device, so the fuse needs to be sized according to the wire you use. The Refrigerator Optimizer uses just a few milliAmps, so a glass tube fuse of 250mA would be adequate if you use a thin wire.

Temperature sensor

The supplied sensor(s) have three wires:

- The black wire is the minus, which needs to be connected to the Tsens- terminal.

- The yellow wire is the data line, which needs to be connected to the TsensDat terminal.

- The red wire is the plus 5V, which needs to be connected to the Tsens+ terminal if your cable run is more than 2 meters. Otherwise you can connect it to the black wire.

If you use two sensors, you can wire them in parallel. This means you can tie all the wires with matching colors together. You can either have the splice inside the refrigerator, or at the terminals of the Refrigerator Optimizer.

If you use an already existing temperature sensor inside the refrigerator, it has two wires instead of three, and you connect them between the Tsens- and TsensD terminals. The polarity is in this case not important. Note that in this case you can not use dual sensors, as you can only wire the supplied digital sensors together.

BD Compressors

If your fridge has a Secop (formerly Danfoss) BD35/BD50/BD80 compressor, which is the case in at least 95% of all cases, make sure that you disconnect anything already connected to the "D", "C", "P" and "T" terminals of the compressor. You actually only need one wire to control the compressor: the compressor terminal labeled "T" needs to be connected to the terminal labeled "Control" on the Refrigerator Optimizer.

If you want to connect the diagnostic output of the compressor to the Refrigerator Optimizer, which is recommended, you run a wire from the "D" terminal from the compressor to the "D" input of the Refrigerator Optimizer.

Other Compressors

In the rare case that your refrigerator is not powered by a BD-compressor, you should have ordered the optional relay addition and use the associated relay output to replace the original thermostat output. The original thermostat has two wires, after discarding the thermostat you connect these two wires to the terminal labeled "Relay out", the order is not important.

In some cases it is also possible to use the negative open collector output of the "Remote relay" terminal directly, without using a relay. Whether this is possible is outside the scope of this manual. If in doubt, just use the relay.

The compressor diagnostic feature is only compatible with the BD-compressors, so leave the "D" input unconnected.

Fan

On the BD-compressor the fan is typically connected between a terminal labeled "+" and a terminal labeled "F". If you want to have the fan controlled by the Refrigerator Optimizer, you disconnect the wire from the "F" terminal and connect it instead to the "Aux" terminal of the Refrigerator Optimizer.

If you are building your own refrigerator, or your compressor is not a BD-compressor, you can also connect the positive fan wire to the system bus, and the minus to the "Aux" output of the Refrigerator Optimizer. This has the additional advantage that it prevents the dreaded BD error #2 (Fan overload) if the fan draws more power than the BD-controller can supply. In this case the fan voltage must match the system voltage.

The "+" terminal of the BD-compressor is a 12V output, even on 24V systems! Hence any fans connected to this terminal are always 12V fans, and should not be connected directly to a 24V system bus.

Commissioning

Once everything is installed, it is time to power up the Refrigerator Optimizer for the first time.

If you are impatient, and want to "play" with the Refrigerator Optimizer before you commit yourself to the installation, it is important that you connect at least the temperature sensor. If the Refrigerator Optimizer can not find a temperature sensor it will halt the startup process with an error message (for obvious reasons).

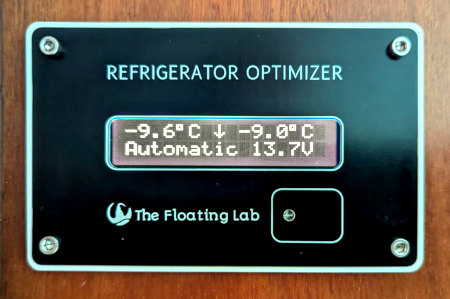

Wait until the normal operational screen appears. It shows the temperature and says "Automatic" on the bottom row.

Read the Menu section first, so you understand how to navigate the menu system.

There are a few settings that are important, like the System Voltage (12/24V), whether the refrigerator is a fridge or freezer, and whether you want to see the temperatures in Celsius or Fahrenheit. You can find these settings in the Setup Menu.

General notes

Factory reset

There are two ways to reset the configuration to the factory values:

- Via the setup menu

- In the setup menu, scroll to "Factory reset", select it, and change it to Yes. A reboot will follow immediately upon exit of the menu and all settings will have reverted to the factory values.

- Via the boot menu

- Reboot the Refrigerator Optimizer, and as soon as the LED turns off, touch the touch sensor and hold it until the "Hold button to reset sensors" message appears. Release the button. Hold it again when the message "Hold button to Factory Reset" message appears, until the message "Reset OK" appears.

Changing the sensor configuration

If you change the sensor configuration, add an additional sensor or replace a broken sensor by a new one, you will have to reset the sensor configuration.

There are two ways to do this:

- Via the setup menu

- In the setup menu, scroll to "Sensors reset", select it, and change it to Yes. A reboot will follow immediately upon exit of the menu and a search for the sensor configuration will be carried out.

- Via the boot menu

- Reboot the Refrigerator Optimizer, and as soon as the LED turns off, touch the touch sensor and hold it until the "Hold button to reset sensors" message appears. Hold the button until the "Sensors reset" message appears.

It will search for new sensors and tell you how many it has detected.

If you have two sensors connected (only possible with digital sensors), you might have to swap the sensors, either physically or in the menu. In case of the latter, scroll in the Setup menu until you find the the "Swap sensors" option and select it.

Switching the Refrigerator Optimizer on and off

It is best to keep the Refrigerator Optimizer always powered on, and use the menu option to switch the refrigerator off if necessary. Reasons to keep the Refrigerator Optimizer running at all times are:

When the compressor is not running, the Refrigerator Optimizer enters sleep mode and uses less than 1mA. So you will hardly save any power by switching the Refrigerator Optimizer off.

If the compressor is switched off for any reason (like reaching the target temperature) it can not be restarted until at least three minutes have passed. This to allow the high pressure from the compressor exit to bleed off, and also to prevent rapid cycling. Due to this, when the Refrigerator Optimizer is powered up and has no idea how long the compressor has been off, it will wait four minutes before it activates the compressor.

One of the key features of the Refrigerator Optimizer is the Adaptive Energy Optimization. What it means is that the compressor is started on the lowest speed (unless there is a big difference between the current temperature and target temperature), and that the compressor speed will slowly ramp up. When the target temperature is reached, the compressor is stopped but the last speed will be remembered and used as a reference when the compressor has to be restarted again. The starting speed will be lowered each time the target temperature is reached, until a balance is found where the compressor runs on the speed necessary to maintain the target temperature. This balance will naturally change when the environment temperature or other variables changes, but the algorithm of the Refrigerator Optimizer will quickly find the new balance. All this tuning information is however lost when the Refrigerator Optimizer is powered down.

This Refrigerator Optimizer is equipped with a hardware watchdog. If a certain point in the software is not passed at least every 4 seconds, it will reset its microcontroller. In case of a nearby lightning strike or a software glitch, the Refrigerator Optimizer will recover by itself. There should never be a reason to cycle the power.

If the Refrigerator Optimizer is not powered, but connected to a powered refrigerator, some leak current from the refrigerator will find its way into the Refrigerator Optimizer and it will (partially) power up, leading to unpredictable results. This happens especially when you have the "Aux" (fan) output connected.

Usage

Liquid Crystal Display

The LCD will show a variety of information.

- Current temperature

- The current temperature is displayed on the top left corner. You can either select Celsius or Fahrenheit in the setup menu.

- Trend

- Behind the current temperature there is an arrow pointing up or down, which shows the trend of the current temperature.

- Target temperature

- The target temperature is displayed on the top right corner. This is the temperature the refrigerator aims to achieve. The target temperature might change when the operating mode (automatically) changes. In some situations the target temperature will be replaced by something else:

- "LowVolt". The compressor is switched off because the system voltage dropped below the "PowerDn Voltage".

- "Pause". The compressor is temporarily switched off because the system voltage dropped below the "Pause Voltage".

- "Defrost". The compressor is temporarily switched off because of an automatic defrost cycle.

- Operation mode

- This is displayed in the lower left corner. The operating mode is selected in the main menu.

- Voltage

- The voltage, as seen by the Refrigerator Optimizer, is displayed in the lower right corner. The voltage determines the target temperature in automatic mode.

- Compressor power

- The last character on the bottom row indicates the compressor power. It is blank when the compressor is not running, and shows a "chevron" that becomes larger when the compressor is running faster.

- Compressor fault

- In case of a BD-compressor error, the display changes and shows the error condition of the compressor.

LED

The LED, embedded in the touch sensor, by default confirms touching the touch sensor. However, in the setup menu you can choose to have the LED show other things instead:

- Touch

- This is the default LED mode. It will just light up when you touch the touch sensor.

- Compressor

- In this LED mode, the LED will light up when the compressor is running.

- Boost

- In this LED mode, the LED will light up when boost mode is either manually or automatically activated.

- Error

- In this LED mode, the LED will light up when a temperature alarm is issued, or when there is a BD-compressor error. In the latter case it will blink in unison with the BD diagnostic LED output.

Menu interface

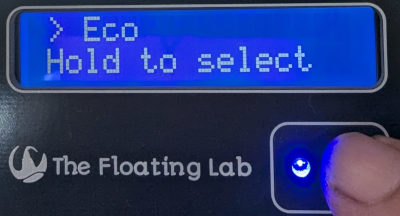

Navigating the menu is easy with the touch button interface. The touch button is the rounded square on the front panel. You can either tap or hold this touch button. By default the LED will light up when the sensor detects your finger.

- Tap

- This means shortly touch it. This is used for menu navigation and progressing through options.

- Hold

- This means keeping the finger on the touch button until the menu changes. This is used for selecting and confirming an option.

When editing a setting in the setup menu, after tapping to the selected value, you always have to confirm the change by holding the button until the "edit mode" is exited, indicated by the > arrow moving to the top row.

When a numeric value needs to be adjusted in the setup menu, tapping the button will increase the value step by step. To lower the value, you have to tap until the upper limit is reached and the number wraps back to the lowest value. The menu is designed in such a way that the difference between the lowest and highest value is rarely more than 15 steps. Most of these options are only set once during setup, to be never altered again.

Main menu

The main menu is used to select the operating mode. Tap to browse through the menu, hold to select the displayed mode. To exit the menu without selecting another mode, just stop interacting, and the menu will time out.

- Automatic mode

- This is the default mode. It will automatically switch between Boost and Eco mode depending on system voltage, and it will select defrost mode when the time is due.

- Boost mode

- Although boost mode will be automatically selected by the Automatic mode, you might want to override this in the following scenario's:

- You want your beverages to be colder on a different time than normal, because you are receiving visitors and/or having a party.

- You are going to shop, or caught a big fish, and you want your refrigerator to anticipate receiving a big, not so cold, load soon. By lowering the temperature in advance you use the content of the refrigerator as a cold bank so the new content will be cooled faster.

- Eco mode

- This can be used to prevent the boost mode from kicking in.

- Defrost

- In this mode the compressor will be turned off, but the evaporator fan (if equipped) will keep running. If you have an additional temperature sensor on the evaporator plate, the defrost mode will exit automatically when the evaporator temperature raises above the freezing point, indicating that the frost has melted off.

- Off

- As you might have guessed already, this turns the refrigerator off.

- Setup

- If you select this, you will enter the Setup menu.

Setup menu

- System volts

- Although the Refrigerator Optimizer will automatically detect the system voltage when it first powers up, you can override the system voltage here. You can toggle between 12Volt and 24Volt. Changing the voltage will reset all configurable voltages to their respective default values. It also changes the voltage range in the setup menu.

- Cooling range

- You can toggle between "Fridge" and "Freezer". Changing this will reset all configurable temperatures to their respective default values. It also changes the temperature range in the setup menu.

- Temp units

- You can toggle between a display indication in "Celsius" or "Fahrenheit".

- Target temp

- The target temperature is the temperature in non-boost (Eco) mode. Select here the highest allowable temperature.

- Boost temp

- The boost temperature is the temperature in boost mode, either manually or automatically selected. Select the lowest allowable temperature. As this mode is automatically selected when a charge voltage is detected, and an abundance of energy is available, select a lower than normal temperature to store extra "cold" energy in the refrigerator.

- Alarm temp

- When the refrigerator becomes at any point longer than 10 minutes warmer than the alarm temperature, it will show an alarm symbol on the display (and light up the LED when it is configured in "error mode"). The idea is that when during a multi day absence the system voltage drops to a point where the compressor shuts down, you will be notified that this has happened. This can happen either due to lack of solar power input, or a shore power failure. When the power returns later, the temperature will drop again but the alarm condition remains, so when you return to the boat you will be alerted that the content of the refrigerator has exceeded a certain temperature limit and some food might no longer be safe for consumption.

- Boost voltage

- When this voltage is reached, the operating mode automatically changes into "Boost mode", as can be seen by the change in "Target temperature" on the LCD. You can, depending on your energy setup, either choose to go into boost mode when a charge voltage is detected (let's say a voltage above 13.7 Volt), or when a "battery full" voltage is detected, like 14.4 Volt. Note that this is a trigger voltage, once the boost mode is triggered, it will remain active until the voltage drops below the "Return voltage".

- Return voltage

- When the automatic "Boost mode" is activated, it will stay activated even when the voltage drops under the "Boost voltage". Boost mode will only be exited when the voltage drops below the "Return voltage". This prevents constantly cycling between Eco mode and Boost mode, but it also allows you to wait until the batteries are close to fully charged before boost mode is selected, and then keep it engaged until the voltage drops below the "float voltage".

- Pause voltage

- If the system voltage drops below the Pause voltage the compressor is (temporarily) stopped. You can select a voltage here that indicates a high system load (like an activated anchor winch, induction stove, or other power hungry device) so the battery sees less load. The pause condition will be cleared when either the voltage increases above the Pause voltage or after 15 minutes, whichever comes first.

- PowerDn voltage

- If the system voltage drops below the Power Down voltage the compressor will be stopped, until the voltage increases again. This is intended to protect the battery or to keep more essential equipment running longer.

- Min ComprSpeed

- The default value of the Minimum Compressor Speed is 1. This is the lowest possible speed of the compressor. In case of a very large refrigerator, where a higher compressor speed is needed all times, you can increase the minimum speed so that the Refrigerator Optimizer doesn't even try to see if that low speed can be used "to keep up". Each level equals a difference of about 300 RPM.

- Max ComprSpeed

- The default value of the Maximum Compressor Speed is 6, which is the highest possible speed of the compressor. In case your electrical system can not provide the power needed for this high speed, or the compressor/condenser tends to overheat, you can cap the maximum speed to a lower value. Each level equals a difference of about 300 RPM.

- Ramp up after XX minutes

- Here you can specify after how many minutes of activation the compressor needs to be stepped up to a higher speed. The default value of 20 minutes per step (which equals an initial 2 hours to go to full power) works fine in most cases, but in very large fridges and/or fridges with a large "thermal inertia" (like a fridge full of beverages), a slower ramp up time can work better. This is a fine tune option. Let us know in the comments section of the website what the sweet point is for your specific setup.

- LCD brightness

- As you guess, this defines the brightness of the display.

- LCD timeout

- You can specify the amount of seconds after which the LCD backlight should be switched off if the button is not pressed. This to save energy or light pollution. If the value is zero, the LCD backlight will stay on indefinitely. If the LCD timeout is activated, the first button press will be "used up" for switching on the backlight.

- LCD glow

- After the LCD has timed out, the LCD will be completely dark, unless you switch on the LCD glow feature. This will allow a very small leak current through the backlight, so it "glows in the dark".

- LED mode

- With this option you can select the LED mode according to the operations described in the LED chapter.

- Hysteresis

- This defines the "window" in which the temperature needs to be maintained. This option is of relevance for small fridges where even the lowest compressor speed is still too much to prevent reaching the target temperature rapidly. A smaller hysteresis value will maintain the temperature more precisely, but at the expense of more frequent on and off cycling which lowers the overall efficiency. To illustrate what it does: If you have a hysteresis of 2 degrees, and a target temperature of 5 degrees, the compressor will switch on when the temperature climbs over 6 degrees, and then shuts down when the temperature has dropped to 4 degrees. The larger the hysteresis, the less frequent the compressor cycles on and off, but at the expense of a larger temperature variation.

- Fan Delta Temp

- This option is only relevant for those who have installed the additional temperature sensor on the evaporator and have an evaporator fan. This option specifies until what temperature difference the fan needs to run. A lower difference will harvest more "cold" from the evaporator faster but causes the fan to run longer (maybe even indefinitely if the compressor starts up again before the evaporator has released all its energy).

- Defrost each XX days

- This menu option only exists in the "Fridge mode", and it only works when you have the additional evaporator temperature sensor installed. You can specify the number of days after which the evaporator needs to be defrosted. What it does is waiting for a good moment to start the defrost cycle (like after a return from boost mode when there is a lot of time available for the evaporator to rest), then prevent the compressor from starting and keeping the evaporator fan (if installed) running, until the evaporator reaches an above freezing temperature which indicates that the frost has been melted off. It will then revert to Automatic mode. A shorter interval means the frost will be melted off quicker, but the defrost mode will be entered more frequently.

- Compressor type

- This option is of relevance only to the "24h Power Log" feature. You can select your type of compressor so that the power logging algorithm knows which profile it has to use to estimate the power consumption. It doesn't affect the operation of the Refrigerator Optimizer in any way, so if in doubt, don't worry about it. You can find the compressor type in the specifications of the refrigerator, and/or a label on the compressor itself.

- 24h Power Log

- This is not a configuration setting. It just shows the amount of Watt/hours used during the last 24 hours, or if you "select" this option, the amount of Amp/hours used during the last 24 hours. This is not an exact measurement but an estimate based on the power profile of the BD-compressors. It works more accurately if you also have an additional temperature sensor on the evaporator installed. The idea is that you can study the effects of changing environmental temperature, frost buildup, configuration parameters, on the overall power consumption of your refrigerator.

- VoltCalibration

- If you think that the voltage displayed is not correct, you can adjust the calibration here. Note that you must do this with the compressor OFF.

- Volt Correction

- You were advised that you should power the Refrigerator Optimizer from a wiring which is not shared with the refrigerator compressor. But, if you ignored this advice, you will find that when the compressor kicks in, the voltage displayed on the Refrigerator Optimizer will sag. Even in this case, we are here to help you: the Refrigerator Optimizer monitors the average voltage difference with the compressor powered on and off, and it can to some degree compensate for this difference. You can select either ON or OFF, and the proposed correction voltage is displayed on the right.

- Thermistor R

- This option is only used when you choose to use a Thermistor to measure the temperature. The supplied temperature sensor is digital and it ignores this option. If you want to use the built in sensor of a Vitrifrigo, select 5000Ω. Otherwise consult the specifications of the Thermistor or just experiment which is the correct value.

- Thermistor Beta

- Like with the option "Thermistor R" this option is only to be used if you use a Thermistor to measure the temperature. The supplied temperature sensor is digital and it ignores this option. If you want to use the built in sensor of a Vitrifrigo, select 3500. Otherwise consult the specifications of the Thermistor or just experiment to find the correct value.

- Swap Temp Sens

- If you installed the secondary temperature sensor for the evaporator, you have to tell the Refrigerator Optimizer which one is the content sensor and which one is the evaporator sensor. In general, with the refrigerator running, the coldest one is the evaporator sensor.

- Relay hold pwr

- This option is for (non BD-compressors!) relay controlled compressors only. Typically, once engaged, relays need less power to maintain the connection. You can configure the percentage of this hold current, and save some 20mA. This has no influence on the performance of the refrigerator itself.

- Emerg DutyCycle

- This is a contingency configuration for when there is a problem with the (primary) temperature sensor. With this option you can configure a ratio between the *on* and *off* time of the compressor, expressed in a percentage of the "on time". So a percentage of 60% means that the compressor will run for 60% of the time. You just have to find a percentage for which keeps the fridge at approximately the desired temperature without using the temperature sensor.

This option will only work in conjunction with the [special mode](#emerg) setting. - Reboot

- You have installed the Refrigerator Optimizer from its own power source without an on/off switch? Great! But if you want to restart the optimizer without disconnecting it... Well, you can use this option.

- Factory reset

- Select this option if you want all settings to revert back to the factory settings. Note that no confirmation will follow other than a reboot.

- Sensors reset

- Use this option if you replaced the temperature sensor or installed an additional one.

- Versions

- This option shows the software- and hardware versions used, which might be asked for if you need product support.

- Serial number

- This option shows the serial number, which might be asked for if you need product support. You can "select" this option if you want to block the menu timeout.

Special features

Broken temperature sensor

In case of a problem with the temperature sensor you can run the refrigerator in a special mode where the compressor is switched on and off according to a configurable ratio. Once you have configured this ratio (which obviously needs to be above 0%) you have to configure the "Min ComprSpeed" to 6, and the "Max ComprSpeed" to a value from 1 to 5. (No, this is not a type, this "impossible" setting is used to enter this special mode). The compressor will then run at the speed indicated by the "Max ComprSpeed", and will be switched on and off according to the dutycycle configured by the Emerg DutyCycle setting. With some trial and error it should be possible to find a dutycycle where the temperature stays at approximately the desired setting, until the problem with the temperature sensor is rectified.

Emergency mode

If moisture entered the refrigerant, the refrigerator will not work anymore because within minutes a piece of ice will form that will block the capillary tube, totally blocking the flow of refrigerant.

The Refrigerator Optimizer has an emergency mode to deal with this problem: It will run the compressor at its lowest speed, and when the evaporator reaches the freezing temperature it will enter defrost mode, wait until the evaporator temperature increases again, and then restart. This cycles the operating mode between Automatic mode and Defrost mode many times per hour, but it works. The cooling capacity is reduced but still the fridge keeps working until it can be serviced or replaced. This mode has been tested with a fridge that won't cool anymore with a traditional thermostat and has found to be working great!

It only works for fridges (not freezers) and only if an evaporator temperature sensor is fitted.

This mode can be switched on by setting the "Min ComprSpeed" to 6, the "Max ComprSpeed" to 1, (no, this is not a typo, this "impossible" setting is used to enter this special mode), and the Emerg DutyCycle setting to 0%.

Again, this is not a magic "repair" but a way to keep the fridge running until it can be serviced properly by fixing the leak and replacing the refrigerant.

On a healthy refrigerator, this mode is useless and should not be used.

Troubleshooting

The very first thing you have to do is to determine whether the refrigerator or the Refrigerator Optimizer is causing the problem. Fortunately, there is a conclusive test you can do.

- Disconnect the power supply to the refrigerator.

- Disconnect the connection between the "control" output of the Refrigerator Optimizer and the "T" labeled input of the BD-controller (which is the bottom terminal).

- Connect the "T" and the "C" terminals of the BD-controller together. This mimics a closed thermostat.

- Disconnect the "F" terminal. This is the fan, and often the fan has a short circuit which causes the BD-controller to shut down.

- Reconnect the power supply to the refrigerator.

- Wait at least one minute.

- Establish whether the compressor is running. You should be able to feel a slight vibration and/or that the evaporator inside the refrigerator becomes cold. Make sure that you don't confuse the sound and vibration of the condenser fan with the compressor. If in doubt, disconnect the fan if you haven't already done so.

- If the compressor now runs, you can reconnect the fan to the "F" terminal. If the compressor doesn't run after that, the fan is faulty.

- Let the compressor run for at least half an hour. If the compressor stops during this test, there is a problem with the refrigerator, as it should keep running as long as the "C" and "T" terminals are connected together.

If the compressor is not performing as expected when the "C" and "T" terminals are connected together, as is evident of lack of any action or a sufficient temperature drop of the evaporator, the problem is with the refrigerator, NOT with the Refrigerator Optimizer! This is a conclusive test.

Problem with the Refrigerator Optimizer

- Display remains blank

- Check the power supply. If you measure 12/24V between the terminals "Pwr-" and "Pwr+" and the display remains blank, the Refrigerator Optimizer is broken.

- Display shows an incorrect voltage

- If the voltage is much lower than expected, check the power supply by measuring directly on the Pwr- and Pwr+ terminals. If you measure a lower voltage than expected, the obvious cause is a poor or absent connection to the battery. If the connection is broken, the Refrigerator Optimizer may feed from some stray current from the compressor module or a connected fan, in which case it will display a wrong voltage as well.

- Display shows wrong temperature

- Reset the temperature sensors. At boot up, check that it detects the temperature sensor(s). If no sensor is detected, check the wiring and the sensor. If you have dual sensors, check that you are reading from the correct sensor. You can go to the "swap sensors" setup menu option to see both temperatures simultaneously.

If the temperature remains unstable, and you use the digital sensor(s) with the two wire interface, using the three wires will probably solve the problem.

If you use an existing sensor (thermistor) check that you have configured the correct Resistance and Beta in the setup menu.

If the problem with the temperature sensor persists, you can [run the refrigerator with a configurable duty cycle](#special) without temperature sensor, until the problem with the temperature sensor is solved. - Display looks normal

- Perform a factory reset. Check that the current temperature (left) is higher than the target temperature (right). Wait at least four minutes. The "activation" symbol (bottom right corner) should appear. If after one minute after the appearance of the activation symbol the compressor is not running, check the connection between the "control" output and the "T" input of the compressor. If you think the connection should be ok, remove the wire from the "Control" output and connect it to the negative wire ("Pwr-" output). If the compressor then runs, there is a problem with the Refrigerator Optimizer. If the compressor still doesn't run, there is a problem with the wire or the compressor controller.

Problem with the refrigerator

Obviously problems with the refrigerator itself are beyond the scope of the customer support for the Refrigerator Optimizer, but below you will find some helpful hints.

If you have a Secop (formerly Danfoss) BD35, BD50 or BD80 compressor: Connect the "D" terminal of the compressor to the "D" input of the Refrigerator Optimizer. If the compressor has a fault, the fault code should appear on the display.

You can also read the diagnostic code without my Refrigerator Optimizer: Just connect an LED bulb between the "D" terminal and the plus. If it starts flashing, count the number of flashes. The number of flashes corresponds to the fault codes below.

- Fault code 1: Low voltage

- Even if you measure 12 (or 24)Volts on the compressor power supply, the connection can still be poor, resulting in a voltage drop when the compressor tries to start up. The temporary drop might be too fast for a digital multimeter to register. But Fault code 1 can usually be solved by checking/replacing the connection between the refrigerator and the battery.

- Fault code 2: Fan overload

- Disconnect the fan, and try again. If the fault disappears and the compressor starts to run, the problem is within the fan. It can still be turning, but there is probably something wrong with it and it should be replaced.

- Fault code 3: Compressor start error

- This can be caused by a poor power supply (see Fault code 1), by a blockage in the refrigerant, too much refrigerant (did you recently add refrigerant?), or trying to restart the compressor too quickly after it has previously ran.

- Fault code 4: Too low compressor speed

- This error normally doesn't occur. Contact a refrigerator service center.

- Fault code 5: Thermal error

- This indicates that the control module overheats. Let it cool down and try again. If the problem persists, the problem can be a too high ambient temperature, too much refrigerant in the system, or a problem in either the control module or in the compressor. If this problem only occurs when the Refrigerator Optimizer is controlling the refrigerator, but not when it runs with its "C" and "T" terminals connected together, it means that the problem only occurs at high speed. (With the "C" and "T" terminals connected together, the compressor runs on its lowest speed). If this is the case, you can cap the maximum speed to a lower value in the Setup Menu ("MaxComprSpeed") of the Refrigerator Optimizer, until you improved the cooling.

- Protocol error

- The connection between the compressor and the Refrigerator Optimizer is wrong, the Refrigerator Optimizer has no negative power supply, or the control module is broken.

- No fault code, no compressor start attempt, and fan doesn't run

- No power to the compressor, or the control module is broken. Double check you bridged the "C" and "T" terminals of the control module and waited 5 minutes before jumping to conclusions.

- No fault code, compressor runs, but inadequate cooling

- If the compressor runs, but cooling is absent or inadequate, one of the following might be your problem:

- The condenser becomes too hot. Check the condenser fan, and check the ventilation of the enclosure.

- Only a part of the evaporator becomes cold, and this part has become smaller over time. This indicates a lack of refrigerant. Obviously you are dealing with a refrigerant leak, just refilling the system will only be a temporary solution if the leak has not been repaired first.

- The evaporator has no frost and doesn't become cold. There might be too little or no refrigerant at all in the system. Check the current the compressor is taking. It should be at least 3 Amperes (or 1.5Amps if you have a 24V system). If the compressor has nothing to compress, the current will be way less, and this confirms the diagnosis. Obviously you are dealing with a refrigerant leak, just refilling the system will only be a temporary solution if the leak has not been repaired first.

- Moisture in the refrigerant. This looks like the previous problem, but initially the evaporator becomes cold until some frost develops, then it stops. If you turn the compressor off, and after a few minutes on again, you might see Fault Code 3. What happens is that the moisture inside turns into ice and blocks the flow of refrigerant. The refrigerator needs servicing, but until that time you can try the special Emergency Mode of the Refrigerator Optimizer. Moisture in the refrigerant usually indicates a leak on the suction side, or can be the result of a poorly carried out refill attempt.

- Debris in the refrigerant. There might be enough refrigerant, but an object (rust particle?) is clogging the evaporator, usually at its entrance. If you turn the compressor off, and after a few minutes on again, you might see Fault Code 3. Sometimes vigorous tapping on the evaporator or capillary tube helps (for a while). Purging the system and refilling it with refrigerant might solve the problem, but most likely you will have to replace the evaporator.

- No fault code, but dripping condensation or even ice on the tube between the refrigerator and compressor

- This indicates too much refrigerant. The BD-compressors only need a little refrigerant and tend to be overfilled; many less qualified technicians think that adding refrigerant is a diagnostic tool and/or will solve all problems, which is not true. More refrigerant beyond "enough" does not cool better, on the contrary, it allows the cooling process to take place in the return tube outside of the refrigerator, thereby wasting energy and cooling capacity. It also puts a heavy load on the compressor, leading to accelerated wear, increased power consumption and possibly overheating of the control module. The obvious solution is to bleed off some refrigerant.