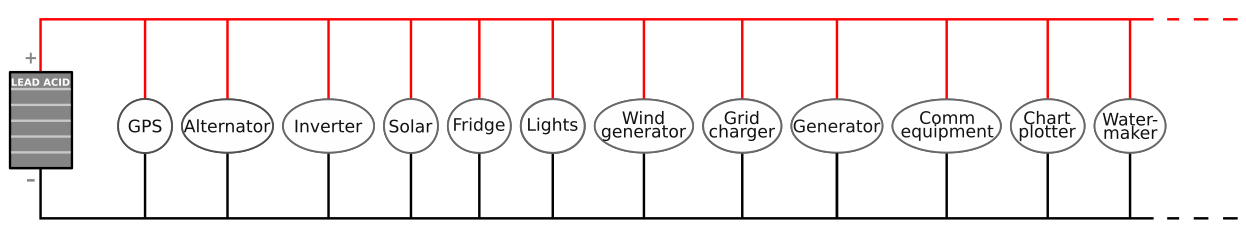

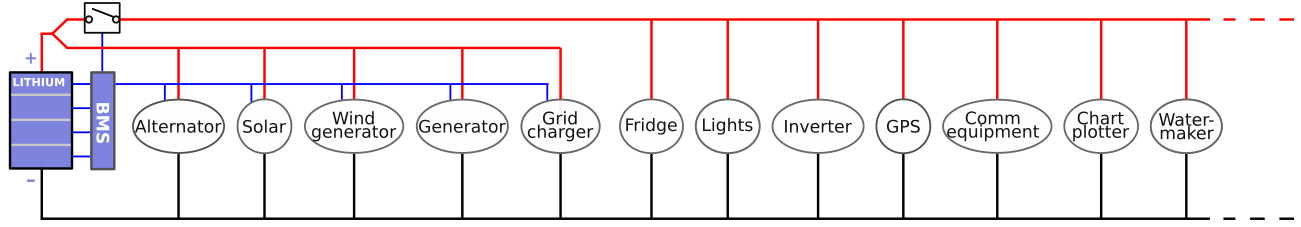

Standard lead-acid installation

This drawing is provided for comparison. Note that usually charge sources and consumers are added at random somewhere on the single power bus (red wire). There is no separation between charge sources and consumers because there has never been a reason to do so.

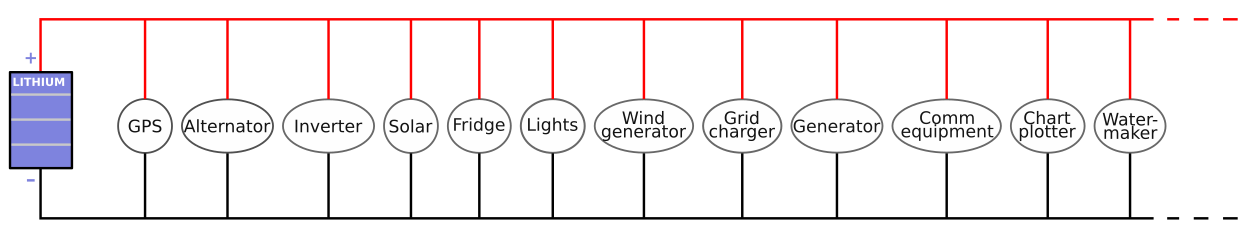

Lithium only, no disconnectors, voltage based regulation

This is also called a "drop in replacement" as no modifications are carried out. Note that the lithium battery may have a BMS, but it is unable to offer much protection (if any at all) because it is unable to disconnect the battery in case of overcharging or overdischarging. Don't get lured into the false notion that the battery may have an internal disconnector. It doesn't, and if it had one, your equipment would fry at the moment the BMS activates the disconnector while the alternator is running.

Advantages

- Single bus: No modifications necessary on existing wiring

- No modifications necessary on charge sources

- Drop in replacement. Cheap and easy.

Disadvantages

- Voltage based charge termination, which can not work reliably

- No protection against malfunctioning charge sources (BMS unable to disconnect the battery)

- No protection against overdischarge, which can change lithium cells into timebombs

- No redundancy (not a major disadvantage in this case, as the BMS will be unable to act anyway).

- Lithium battery needs to be large enough to provide all reserve power, will thus remain most of the time in a highly SOC which is bad for its health.

- No protection against low temperature charging

- No reliable balancing possible

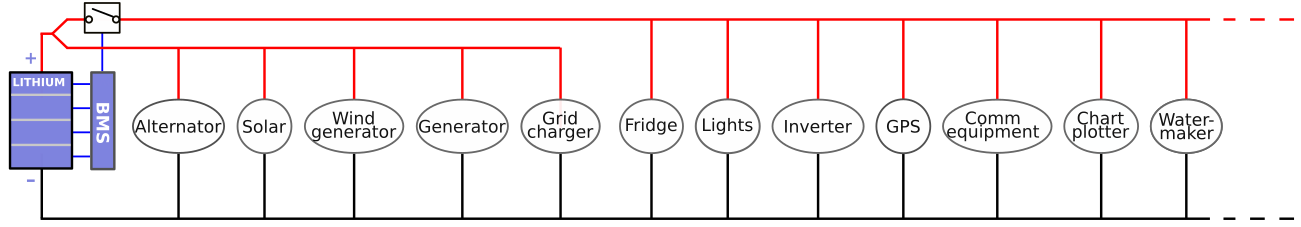

Lithium only, overdischarge protection

Advantages

- No modifications necessary on charge sources

- Protection against overdischarge

Disadvantages

- Dual bus: modifications necessary in wiring

- Voltage based charge termination, which can not work reliably

- No protection against malfunctioning charge sources (BMS unable to disconnect the battery)

- No redundancy. If BMS erroneously activates the overdischarge protection, all equipment goes offline.

- Lithium battery needs to be large enough to provide all reserve power, will thus remain most of the time in a highly SOC which is bad for its health.

- No protection against low temperature charging

- No reliable balancing possible

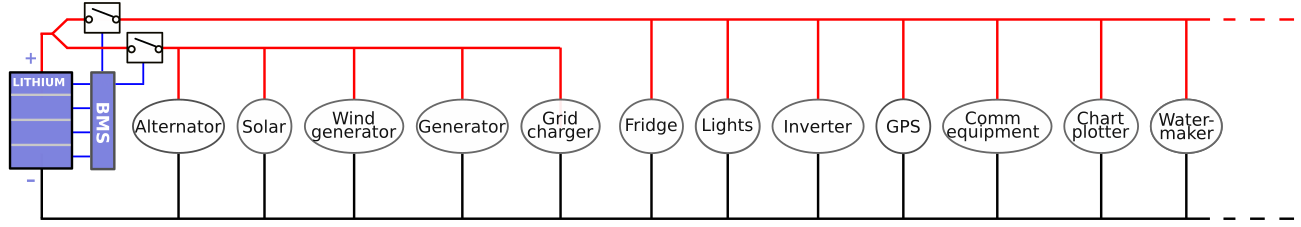

Lithium only, overdischarge proctection, charge termination with interruptor

Advantages

- Properly implemented charge termination

- Protection against overdischarge

- Protection against malfunctioning charge sources (BMS just disconnects the battery)

- Protection possible against low temperature charging

Disadvantages

- Dual bus: modifications necessary in wiring

- Charge sources need to be able to operate without battery. Modifications/replacement of charge sources likely necessary.

- When battery is fully charged, equipment immediately starts feeding from the battery.

- No redundancy. If BMS erroneously activates the overdischarge protection, all equipment goes offline.

- Lithium battery needs to be large enough to provide all reserve power, will thus remain most of the time in a highly SOC which is bad for its health.

- No reliable balancing possible

Lithium only, overdischarge proctection, charge termination by communication

Advantages

- Properly implemented charge termination

- Protection against overdischarge

- Protection possible against low temperature charging

- When battery is fully charged, equipment might be able to feed from the charge sources

- Balancing might be possible

Disadvantages

- Dual bus: modifications necessary in wiring

- Modifications/replacement of charge sources necessary.

- No protection against malfunctioning/disobeying charge sources (BMS unable to disconnect the battery)

- No redundancy. If BMS erroneously activates the overdischarge protection, all equipment goes offline.

- Lithium battery needs to be large enough to provide all reserve power, will thus remain most of the time in a highly SOC which is bad for its health.

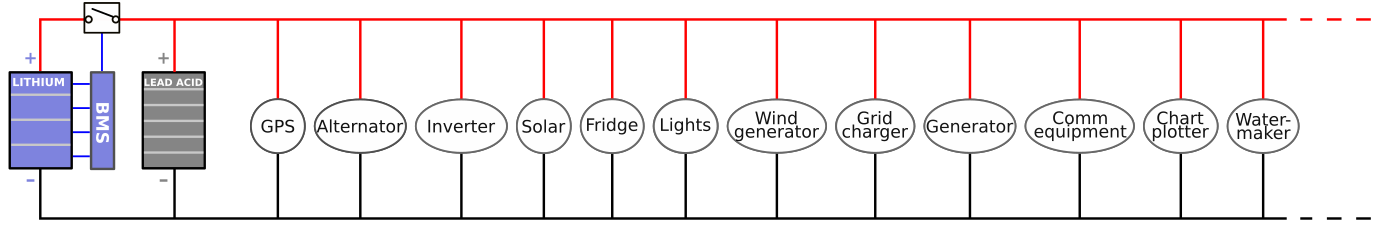

Lead-acid/Lithium hybrid

Advantages

- Single bus: No modifications necessary on existing wiring

- No modifications necessary on charge sources

- Properly implemented charge termination

- Protection against overdischarge

- Protection possible against low temperature charging

- Protection against malfunctioning charge sources (BMS just disconnects the battery)

- Redundancy. If the BMS malfunctions, the system automatically falls back to the standard lead-acid configuration

- Lithium battery can be smaller, thus gets discharged deeper, which is good for its health

- When battery is fully charged, equipment will be fed from the charge sources

- Reliable balancing possible without interrupting normal ship operation

Disadvantages

- A hybrid installation is heavier than a a pure lithium installation due to the weight of the lead-acid batteries.

Conclusion

A lead-acid/lithium hybrid implementation clearly offers the most advantages.

Despite its clear advantages, the lead-acid/lithium hybrid implementation is relatively unknown. There might be a few reasons for this:

- Ship owners want to get rid of the pesky lead-acid batteries and only focus on a total replacement by lithium batteries. A hybrid conversion might intuitively feel as a "job half done".

- Lithium battery vendors want to sell as much capacity as possible.

- So far there were no Battery Management Systems specifically designed for hybrid installations.

We hope to bring the advantages from lead-acid/lithium hybrid installations more into the well deserved spotlight. Read more about it on our article about lead-acid/lithium hybrid systems.