We have a Coltri/Maxair gas powered dive compressor, but much (if not all) information on this page also applies to other brands.

One of the annoying and expensive things about operating the dive compressor are the cartridges. They need to be replaced often and once installed they last only 6 months even if you are not using the dive compressor at all. To make matters worse, the cartridges are very expensive and they have a limited shelf life, so you can't stock them up for a few years from a cheap source, but have to buy them somewhere locally or periodically spend a lot of money on shipping and import duties. Quite a few times we opened a new package to find out that the cartridge was already expired due to aging or by a small leak of the packaging, adding to the frustration.

The limited time after the cartridge has been installed was also often causing a dilemma. Are we really going to install a new cartridge just to do that single one dive if we know that the next couple of months we are probably not going to dive again? Or are we going to throw away that barely used cartridge just because it had been sitting a tad too long inside the dive compressor?

There is probably a commercial reason why our cartridges are so expensive and not reusable. The cartridges in commercial dive compressors are refillable and the chemicals are not only exactly the same as in our non reusable cartridges but also way more affordable. The solution would be to refill our cartridges but they are made in such a way that it is impossible to open them up without destroying some parts. This situation reminded me of the frustrating time when you had to buy expensive ink cartridges for printers: while ink is usually very cheap the printer manufacturers were going to great lengths to make it as difficult as possible to refill their cartridges just to encourage you to buy expensive new ones, or to buy much more expensive printers which had "refillable" ink cartridges.

Please understand that the following is just a description of how we operate our dive compressor, we are no dive professionals and our description should not be mistaken as a professional recommendation. We believe the described procedure is safe (we are still alive and have no signs of water in our dive tanks), but do your own research and make your own decisions. When in doubt, by all means just follow the directions of the dive compressor manufacturer and buy their expensive cartridges.

To convert the throw-away cartridges into reusable cartridges you have to take them apart. The main problem with the cartridges is to separate the caps from the tubes. They are solidly glued together (I wonder why?) in such a way that it is impossible to separate them without destroying at least one part. We found a solution to this problem by using two spent cartridges. Don't worry, you will have plenty of barely used but expired cartridges at the time the waste starts bugging you, so you can afford to spoil a few attempts. One cartridge is used to salvage the tube by carefully destroying the cap, and another cartridge is used to salvage the cap by carefully destroying the tube. A dremel is a good tool to help with the destruction of the unwanted part. Just be a little creative with inflicting damage to the unwanted part without touching the wanted part, until the whole thing comes apart. Remove the glue residue and try to achieve a snug fit of the two parts.

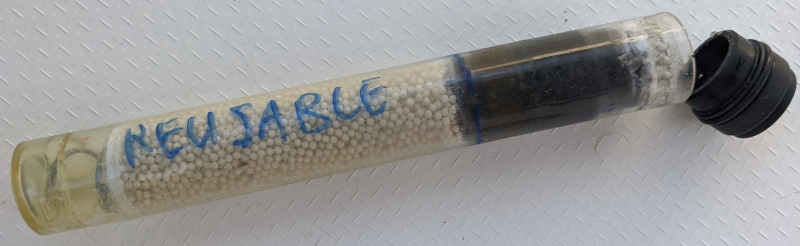

Once you have opened up a cartridge, you will see that there isn't any high tech inside but just a few kinds of grains, separated by cotton disks and pressed together by a spring. Before shaking out the contents, use a sharpy to mark the divisions of the grains in order to have a reference when you refill the cartridge later. Also make sure to clearly mark the cartridge as reusable so you don't accidentally throw the cartridge away out of habit some time later. There are two (electric powered compressors) or three (gas powered compressors) kinds of grains inside:

How do you know your grains are still good?

The original cartridge comes with a colored strip which changes color when moisture is detected. This is used as a verification that the moisture absorbing grains inside the cartridge are still fit for use. But if you refill your cartridge, how do you know the grains you are using are still good?

There is a simple way to test the quality of your moisture absorbing grains:

- Take two identical small jars or glasses. Fill one small jar with some grains, fill the other one with room temperature water to exactly the same level.

- Empty the jar with the water into the jar with the grains. The grains will now quite aggressively react with the water.

- Measure the temperature of the mixture. The temperature should reach about 60°Celsius.

The more the grains have been exposed to water already, the lower the temperature of the mixture. You can compensate a bit for grains that "lost some of their strength" by using them for fewer dive tank refills, but it is of course safe practice to replace them if they fail to reach a temperature of at least 55°Celsius.

It might be an idea to test the "exhausted" grains when you refill the cartridge to verify that they still had some life in them during the most recent dive tank refill, but I have no data yet what temperature would be good. Obviously, if they don't heat the water at all anymore you have used them for too long.

- Moisture absorbing grains. These yellow grains form the largest part of our cartridge. They have the important task to absorb as much moisture out of the compressed air as possible. Moisture in the dive tanks is bad and needs to be avoided at all costs. This is the main reason why you need to replace the cartridge often.

- Carbon grains. They are used to absorb organic material and odors.

- Carbon monoxide absorbing grains (only for gas powered engines). Carbon monoxide is a health hazard, it is not a normal part of the air we are living in but can be found in exhaust fumes from combustion engines. With combustion engine powered dive compressors with a close proximity of the exhaust to the breathing air inlet there is of course a small risk with less careful operators that a small amount of the exhaust fumes finds its way into the air inlet, hence the need for carbon monoxide absorption. Problem with the carbon monoxide absorption grains is that they are very expensive, and it is questionable whether you really need them in case of a proper stationary installation where the air inlet and exhaust are thoughtfully separated from each other. You have three options here:

- Buy a bottle of CO absorption grains and replace the grains every time just to be absolutely sure.

- Keep the existing CO absorption grains and put them back in the cartridge. As long as they haven't been in contact with CO they don't expire and can be reused.

- Don't use CO absorption grains anymore but use the available space for additional moisture absorbing grains.

In our stationary installation on ZwerfCat there is no risk of carbon monoxide reaching the air inlet so we have chosen not to use CO absorption grains in our refill procedure, but to use the available space for additional moisture absorbing grains instead.

Fortunately, there is no need to devise a locking mechanism for the now separated cap and tube. The cap and container will likely loosely fit together and once installed inside the compressor the spring at the bottom of the cartridge container will keep the two parts together. Please make sure that there are no air leaks between the cap and the tube, you can use some silicon grease or a rubber o-ring to prevent air from bypassing the tube.

The original cartridge comes with a colored strip which changes color when moisture is detected. This colored strip only works once and is meaningless once the cartridge has been refilled. Just make sure to refill the cartridge after the recommended amount of dives or before the recommended time has been expired. Since it is now much cheaper to refresh the cartridge there is no excuse anymore to squeeze the last bit of life out of the grains.

Lots of effort goes into the free information pages and services of this website. If you want to show your appreciation and support my efforts, you are welcome to contribute with a donation to my personal Paypal account.